Our strategy

As a world leader in copper recycling and supplier of non-ferrous metals, Aurubis processes complex metal concentrates, scrap metals, and metal-bearing recycling raw materials into metals of the highest purity. Offering around 20 metals, we are essential for the transformation to a more sustainable, carbon-neutral economy.

Our core strength lies in our unique network of copper smelters, recycling sites, and highly specialized metal processing facilities. This unique structure and enormous know-how allow us to process a wide range of materials efficiently and profitably.

Our Metals for Progress: Driving Sustainable Growth strategy is based on three pillars: securing and strengthening the core business, pursuing growth options, and expanding an industrial pioneering role in sustainability. Digitalization, automation in production, strategic resource planning, and personnel management are key factors for success. We leverage targeted, long-term growth projects to optimize and expand our network with the aim of bolstering and consistently broadening our position as one of the most efficient and sustainable multimetal producers in the world.

“Our strategic projects are ambitious — because the future is made of metals!”

— Dr. Toralf Haag, CEO

Securing and strengthening the core business

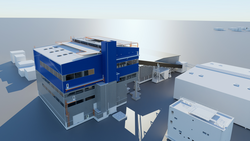

Processing metal-bearing raw materials from concentrates and recycling materials is our core business. We consistently invest in our sites, expanding processing capabilities and increasing metal yield in the smelter network. We aim to further optimize material flows among the plants to take even greater advantage of synergies. With projects like Complex Recycling Hamburg (CRH), we are driving internal value creation, building up recycling capacities, and furthering the circular economy.

Pursuing growth options

The recycling business is growing in importance in Europe and the US, and is a key driver of growth for us. We see ourselves as pioneers in sustainable metal recycling with our new plant, Aurubis Richmond in Georgia, US. The site strengthens our smelter network and offers new diversification opportunities beyond Europe.

We also see huge potential in battery recycling, especially in the recycling of black mass from lithium-ion batteries.

Industry leadership in sustainability

Sustainability is an integral part of our strategy. We are planning a 50 % reduction in Scope 1 and 2 emissions by 2030 — through the use of green hydrogen, by electrifying our production processes, and by expanding the captive generation of clean electricity. We are also targeting a 24 % drop in our Scope 3 emissions per ton of copper cathode and increasing the recycling proportion by up to 50 % by 2030 as well.

Today we already produce copper cathodes with around 60 % lower CO₂ emissions than the global average and we are steadily working on widening this gap.

Status quo

and outlook

In the coming three years, we will execute a series of additional projects to raise the performance of our smelter network even higher.